believe it or not, under the nice aluminum cover lurks a few big problems consumers just don't know about,

1 - overload protection doesn't work

2 - short circuit protection doesn't work

3 - fan is mounted upside down so gravity wants to pull it apart

4 - if the fan fails casing can get hot enough to burn skin

5 - will burst into flames before failing

this particular one failed because of the fan, and i sported a small burn to my finger when i touched the casing of it, here's an autopsy

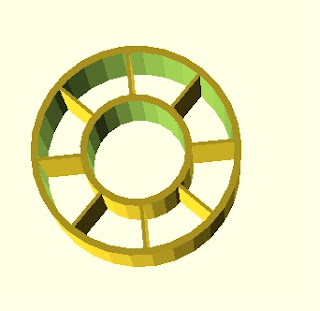

how the fan looks when the cover is off, this faces down and blow air out of the case - this is actually a brand new one i now turn the fans around to stop them from destroying themselves, it make no difference to the running temperatures though

not much to see here,

this is what happens when the fan finally fails with this one i got lucky, that it was just the fan, the previous one self destructed because somthing metalic came away from the fan and shorted somthing it shouldn't, and delivered and nice high voltage to all my stepper drivers and heaterbed, thankfully the drivers were unharmed however the printer had to be completely rewired